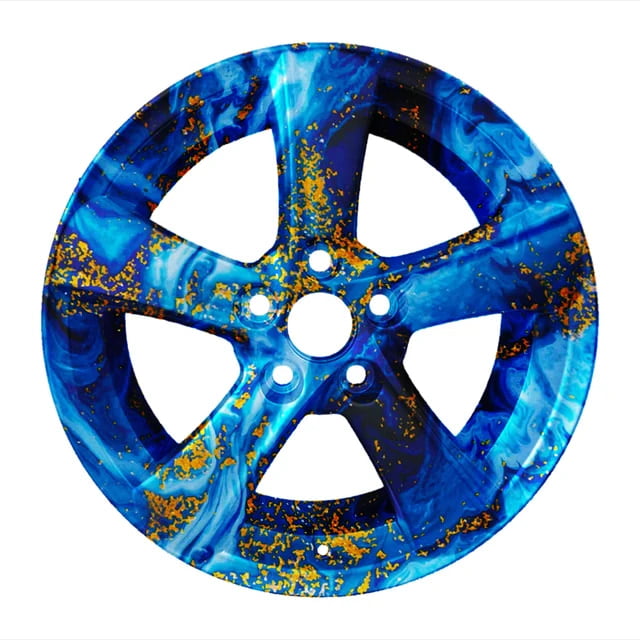

PROFESSIONAL GRADE

RESULTS

Revolutionizing surface decoration with unparalleled precision. From compact hobby tanks to industrial automated arms.

CORE EQUIPMENT

MODEL PD-4 MANUAL

Compact 4-feet solution. Ideal for limited spaces and startups.

MODEL PD-6 STANDARD

6-feet tank balancing size and capability. Includes adjustable rack systems.

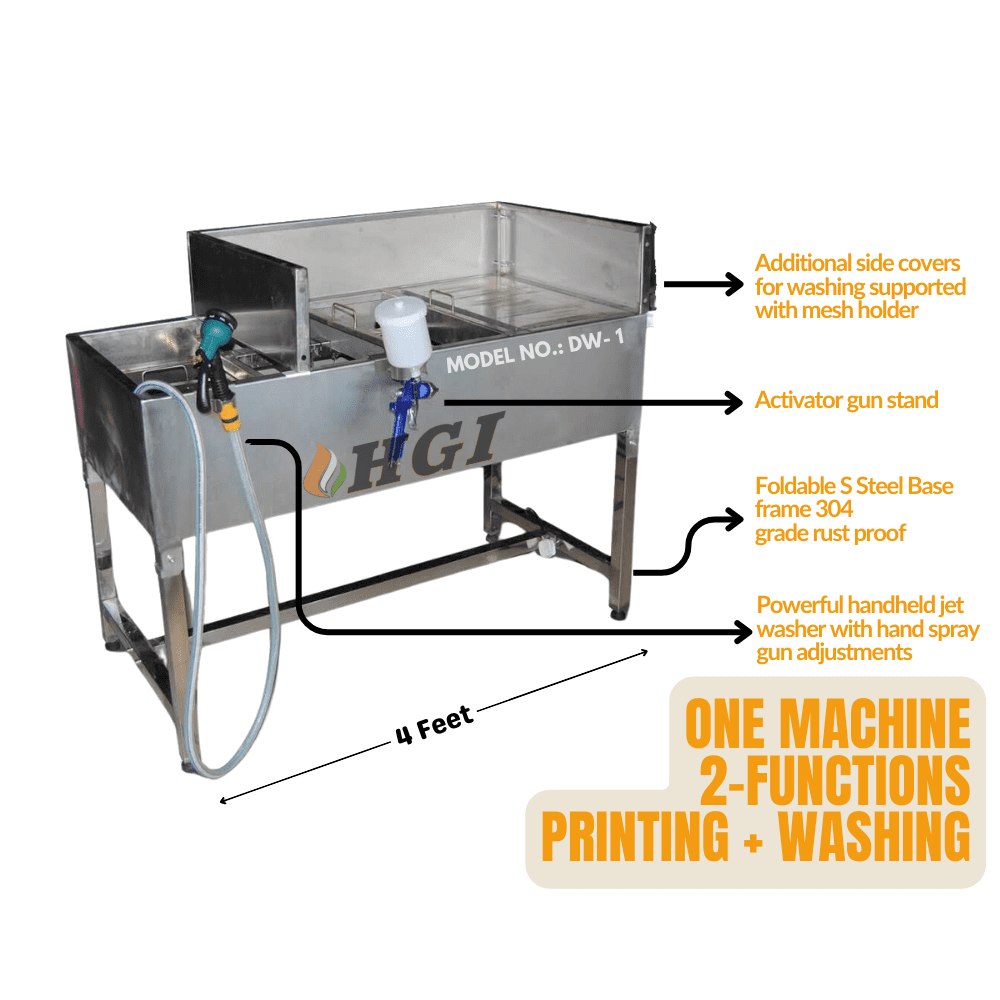

COMBO MINI (DW-1)

Space-saving design combining Dipping and Washing in a single unit.

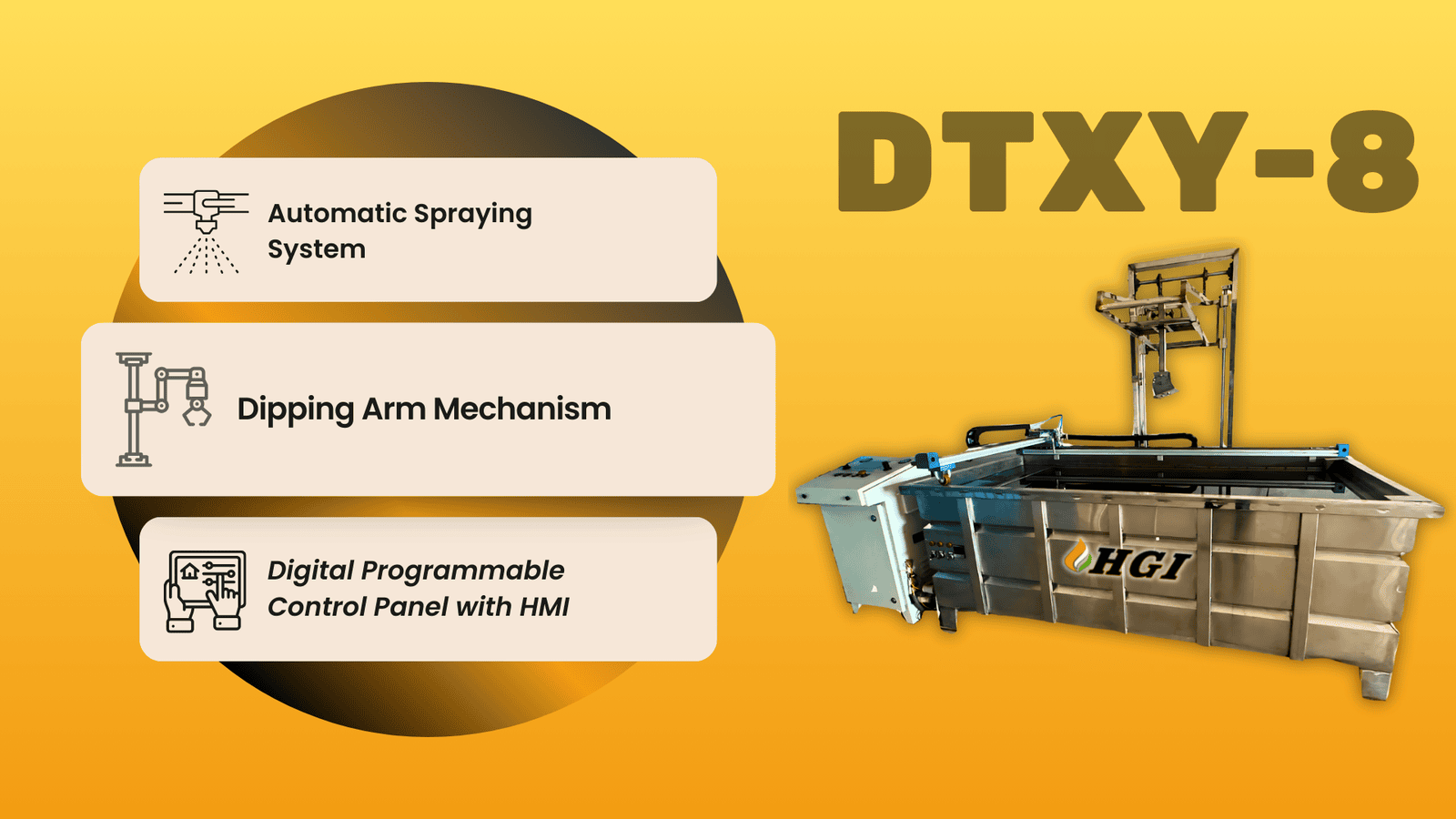

AUTO DIP & SPRAY (DTXY-8)

Includes robotic Activator Spray Plus Dipping Arm System for precision speed and angle control.

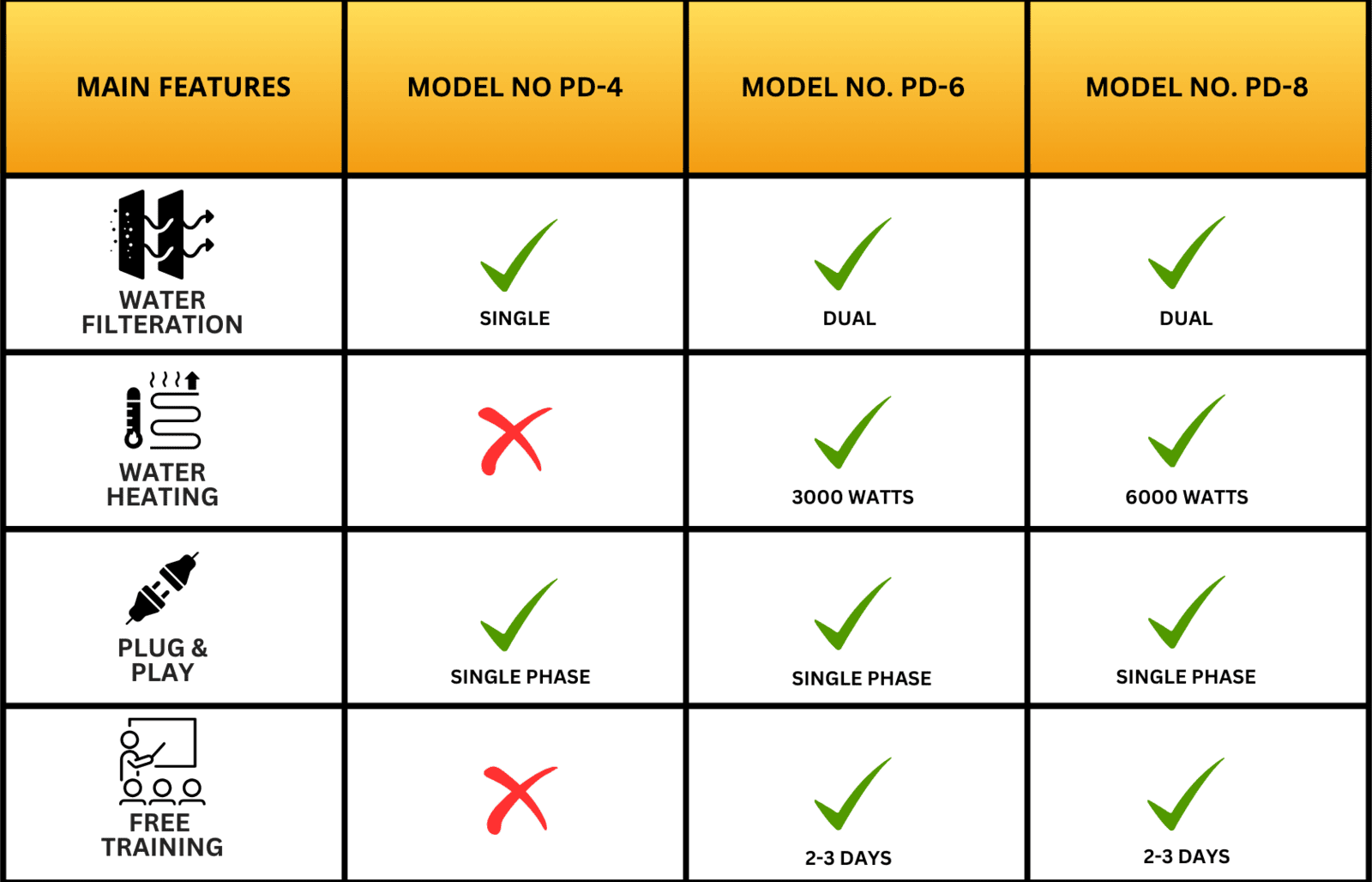

MODEL COMPARISON

Single

Dual

Dual

3000 Watts

6000 Watts

Single Phase

Single Phase

Single Phase

2-3 Days

2-3 Days

MACHINES IN ACTION

VIDEO 1

MODEL:VIDEO 2

MODEL:START YOUR VENTURE

ESTIMATED SETUP COST

- Films₹5,000 - ₹25,000

- Chemicals₹500 - ₹5,000

- Spray Guns₹1,500 - ₹2,500

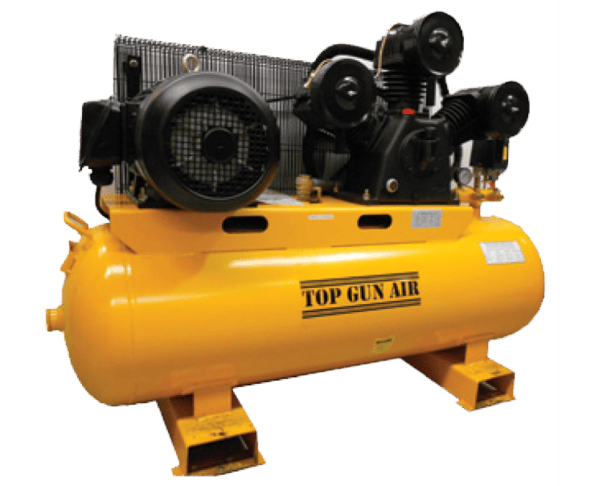

- Compressor₹10,000 - ₹25,000

PROCESS OVERVIEW

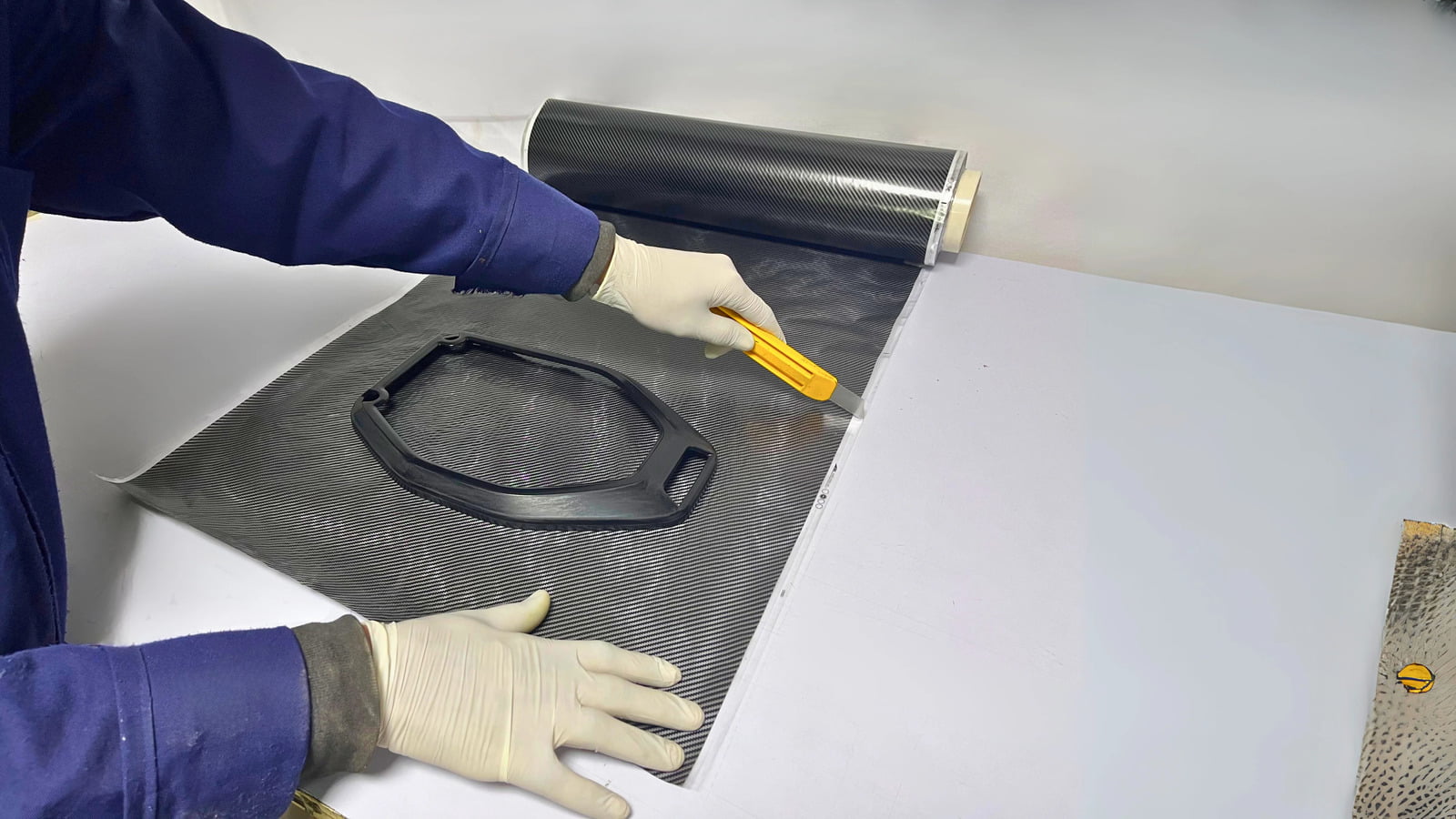

Clean surface thoroughly, sand if necessary, and apply suitable basecoat primer.

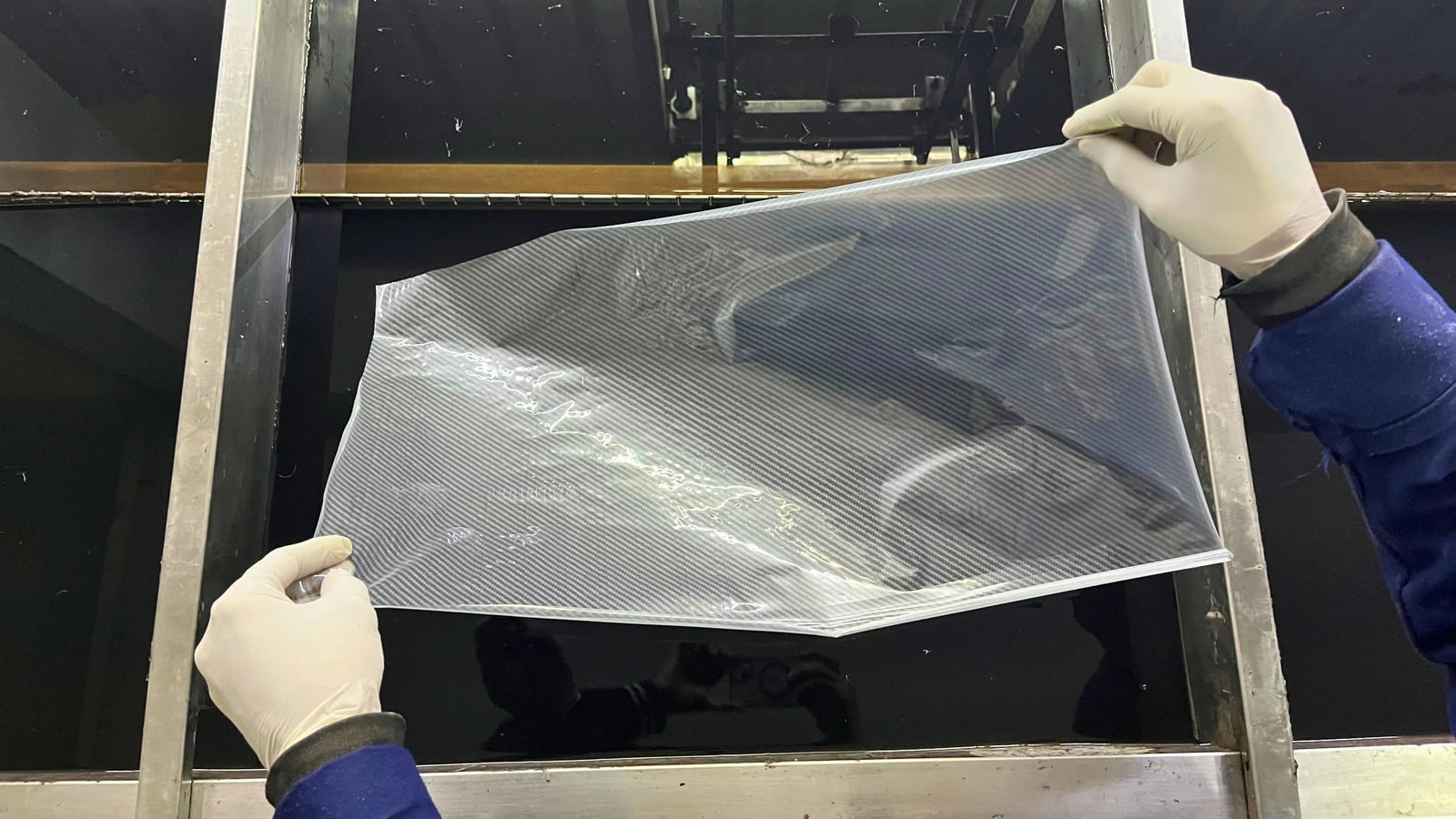

Carefully lay the PVA film on the water surface, avoiding air bubbles.

Apply activator chemical evenly until the film turns into liquid ink.

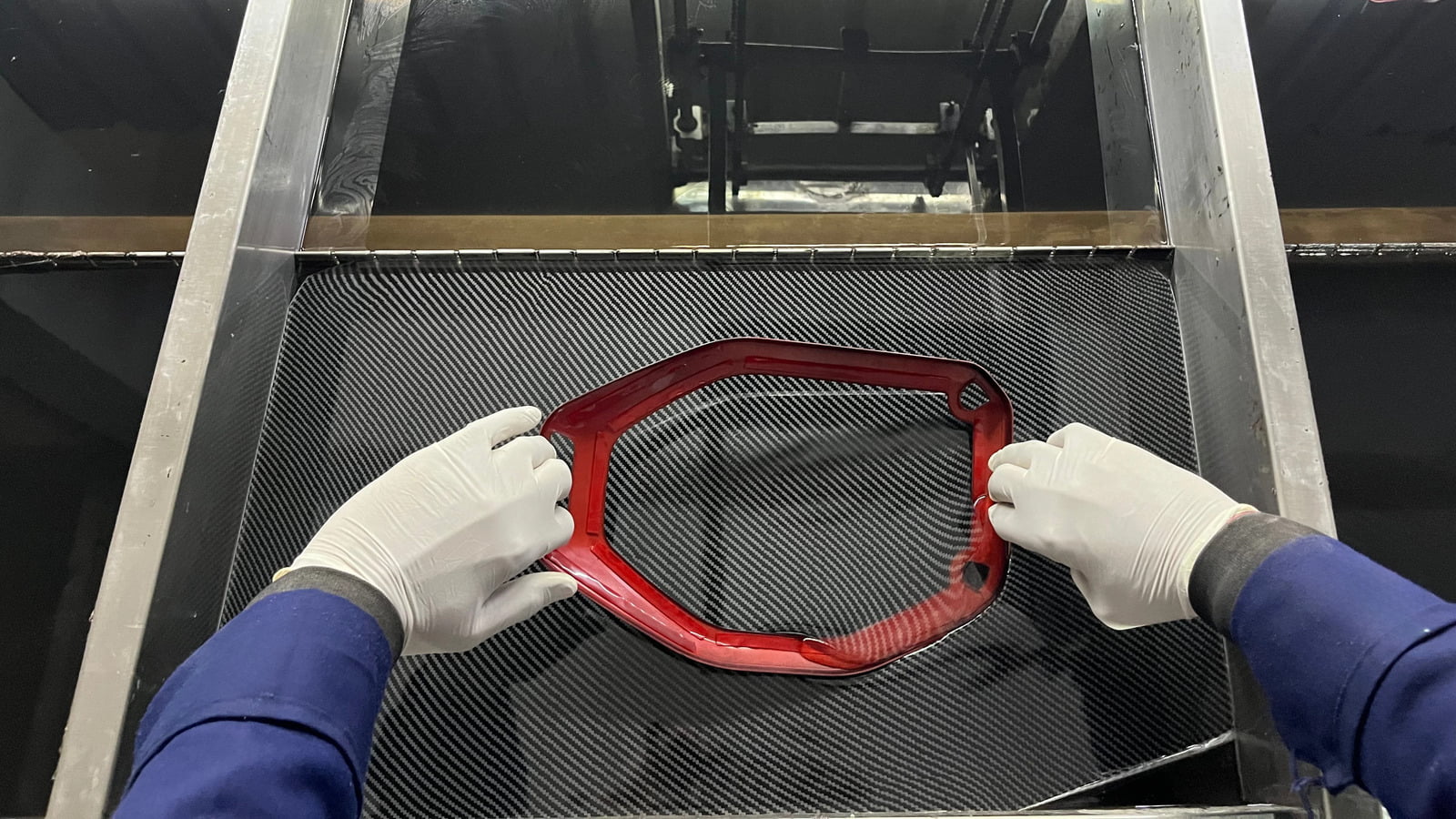

Submerge the object slowly at a 30-45 degree angle to transfer the pattern.

Wash off the slimy PVA residue under gentle running water until clean.

Once dry, apply a durable clear topcoat (gloss or matte) to protect the finish.

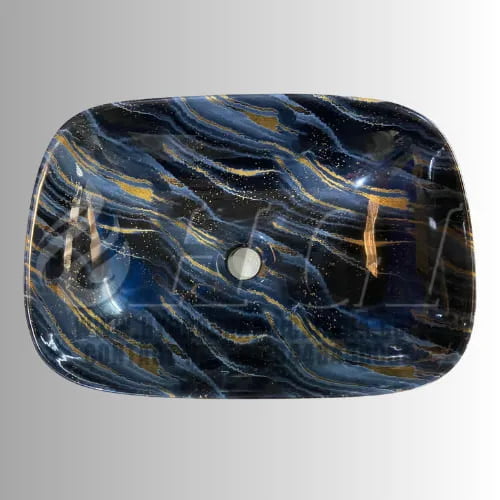

Professional-Grade Results

manual Hydrographics Water Transfer Printing Machines

manual Hydrographics Water Transfer Printing Machines

Manual Dipping Tanks

The dipping tank is the heart of the water transfer printing process. It is a large, water-filled container where the hydrographic film is placed on the surface. The tank maintains a consistent water temperature and provides a controlled environment for the immersion of objects.

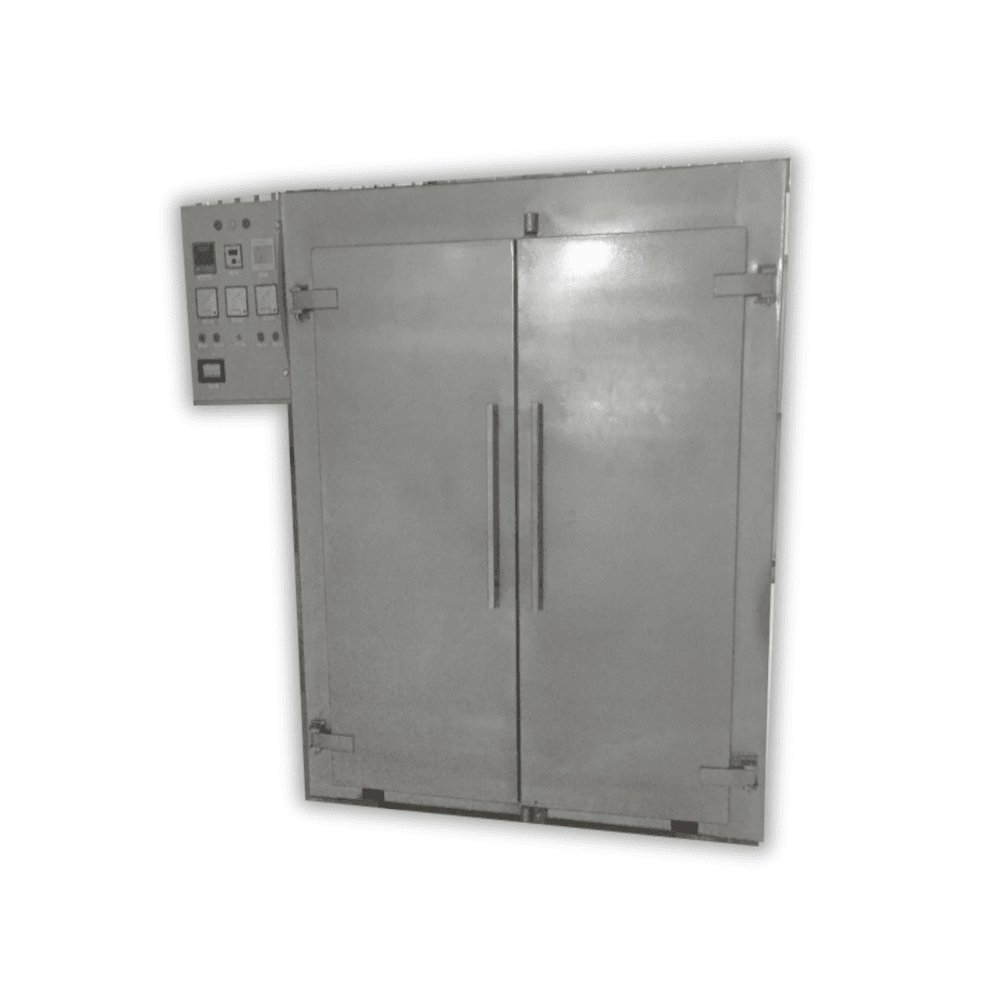

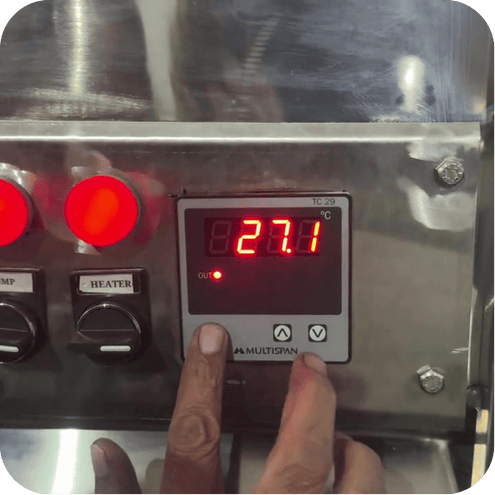

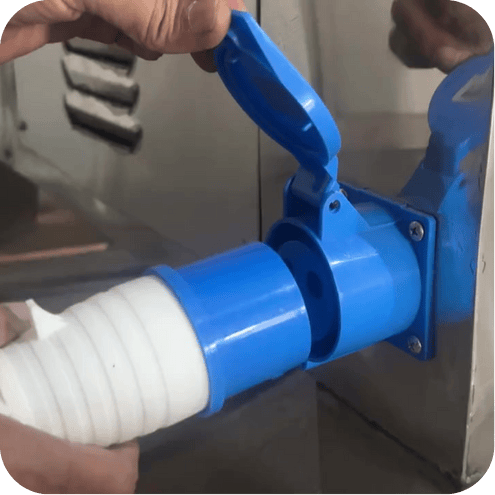

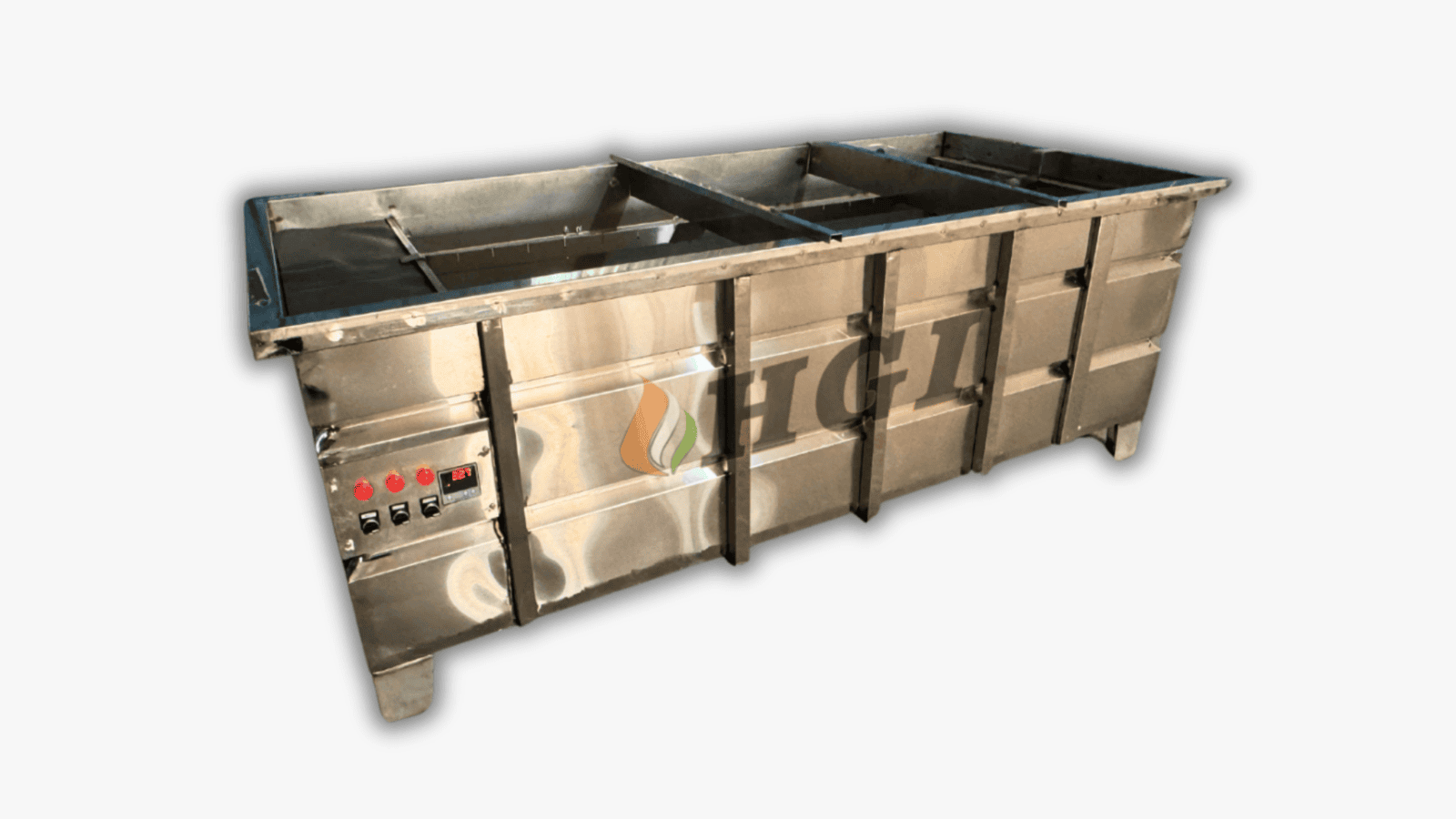

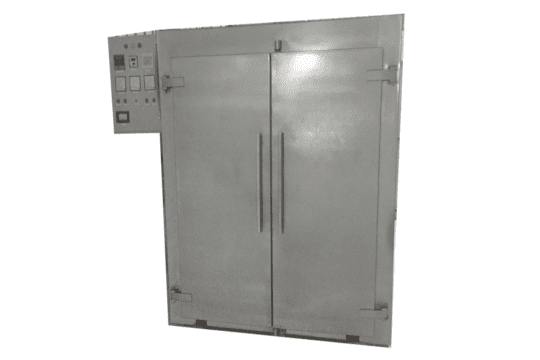

Batch Ovens

A drying system, often comprising heaters or blowers, helps accelerate the drying process of the object after it's been dipped and coated. Proper drying is crucial to prevent smudging, running, or defects in the final appearance.Oven help you to in faster delivery in any weather Condition.

manual

Hydro Dipping Tanks

Hydrographics Tanks plays a critical role in the hydrographic printing process by facilitating the hydration of the hydrographic film before activation. By ensuring that the film is fully hydrated and ready for application, it helps maintain the quality and integrity of the printed design, ultimately contributing to the success of the hydro dipping process.

Hydrographics Tanks plays a critical role in the hydrographic printing process by facilitating the hydration of the hydrographic film before activation.

Features

Most Popular

Dipping Tanks

Most Popular

Dipping Tanks

Model:PD-4

The 4 feet hydro dipping tank offers a compact solution without compromising functionality. Despite its smaller size, it boasts robust construction and efficient heating elements. Its best features include precise temperature control, seamless operation, and easy maintenance. This Its compact footprint makes it ideal for limited spaces while ensuring high-quality results.

Model:PD-6

The 6 feet hydro dipping tank strikes an excellent balance between size and capability. It accommodates a wide range of objects for dipping, making it a popular choice. Its standout features include adjustable rack systems, efficient water circulation, and rapid heating technology. This tank offers versatility and efficiency, enabling users to consistency.

Model:PD-8

The 8 feet hydro dipping tank stands out as a premium solution for large-scale hydrographic projects. Its spacious design accommodates oversized objects and allows for batch dipping, increasing productivity and efficiency. This tank is perfect for industrial applications and large-scale production environments, offering unparalleled performance and reliability.

Get Free Training With Certification & Material*

See Our Hydro Dipping Machines in Action

Watch the Full Video on YouTube Now

For more videos follow us on YouTube for exclusive demos, tips, & tutorials. Don’t forget to like, subscribe & share

For more videos follow us on YouTube for exclusive demos, tips, & tutorials. Don’t forget to like, subscribe & share

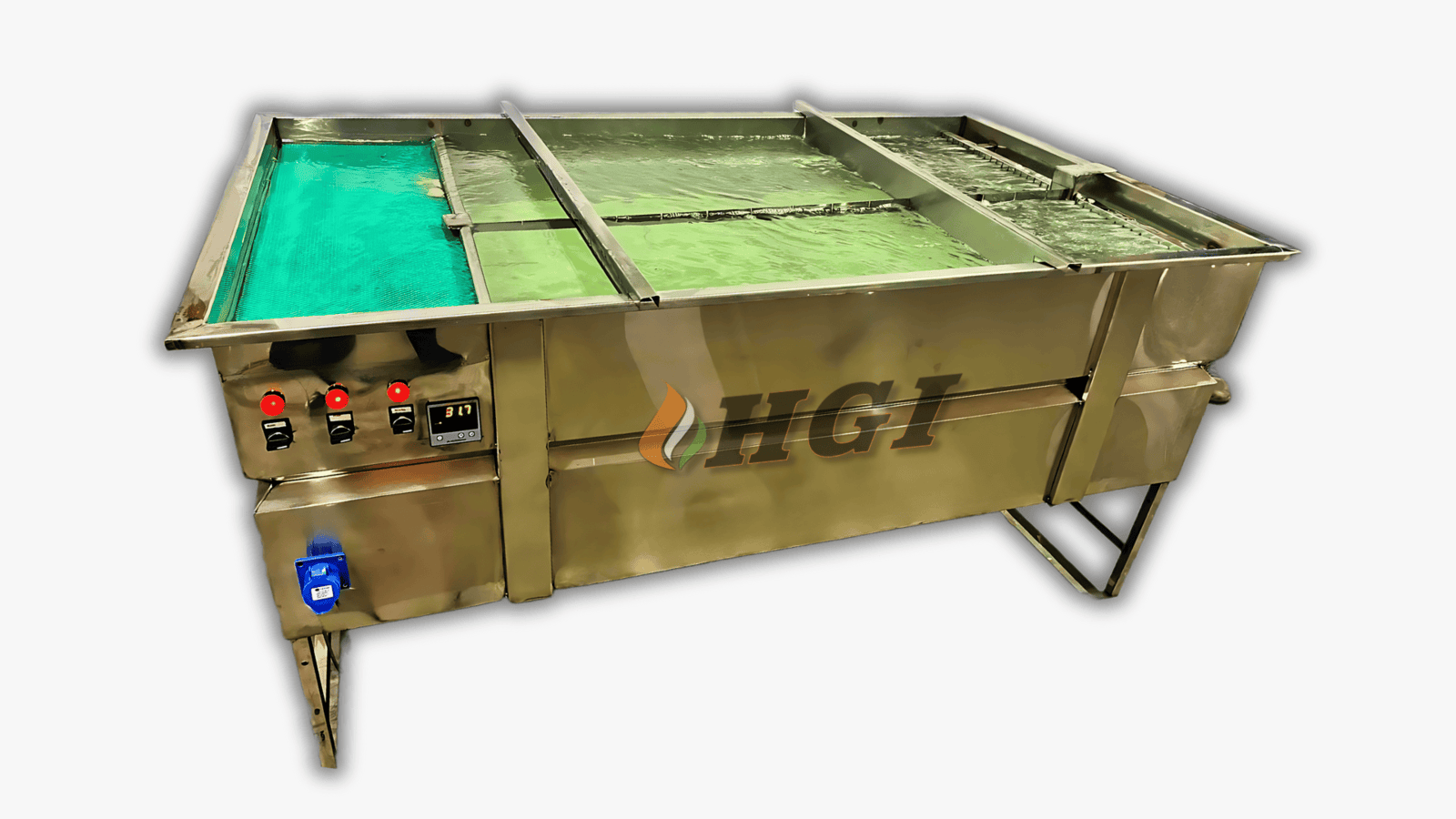

Model

DW-1

Introducing our innovative Combo Mini Tank, a versatile solution that combines dipping and washing systems into one compact machine, streamlining the hydrographic process like never before.

Here are some of its standout features

- Dual Functionality:The Combo Mini Tank seamlessly integrates dipping and washing functionalities in a single unit, optimising workflow efficiency and saving valuable workspace.

- Space-Saving Design:Its compact footprint makes it ideal for workshops with limited space, allowing users to maximise their working area while enjoying the benefits of both dipping and washing capabilities.

- Durable Construction: Built with high-quality materials and components, the Combo Mini Tank guarantees long-lasting performance and reliability, making it a valuable investment for hydrographic professionals and enthusiasts alike.

- Easy Maintenance:The tank features easy-to-clean surfaces and accessible components, simplifying maintenance tasks and minimising downtime, ensuring uninterrupted operation.

Contact Us For Latest Pricing

Contact Us For Latest Pricing

New Launch

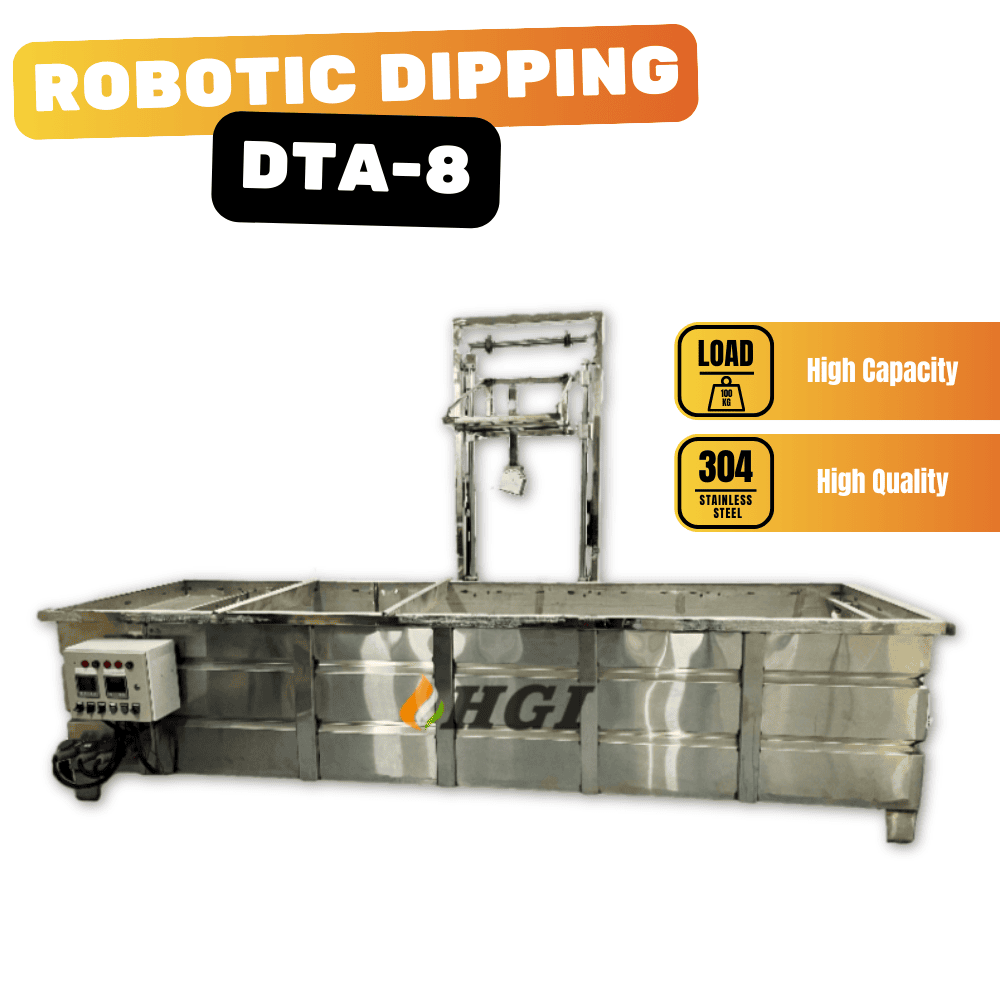

Auto Dip TankS

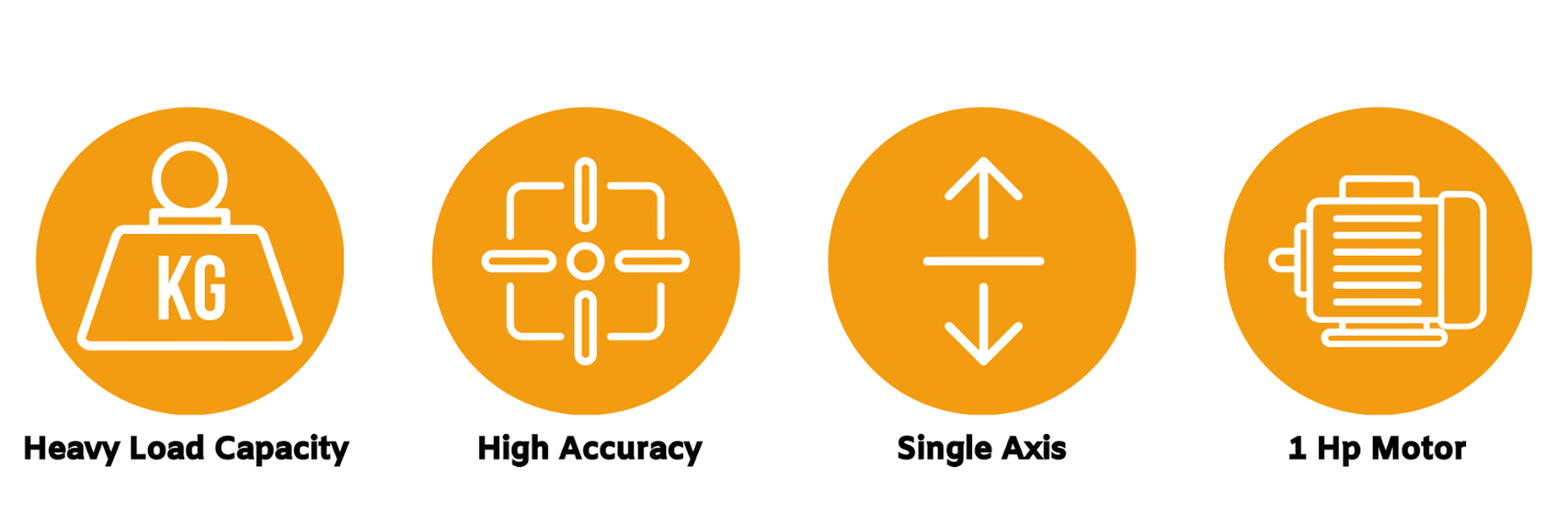

Introducing our Dipping Tank with an innovative Dipping Arm System, revolutionising the hydro dipping process with enhanced precision and efficiency. The dipping arm system offers unparalleled control and stability, ensuring smooth and uniform film application on various objects. Designed for versatility and ease of use, this dipping tank with the dipping arm provides an exceptional dipping experience for users of all skill levels.

Product Details

Model

DTA-8

Dipping Tank + Dipping Arm System

Introducing our innovative Dipping Arm System Tank, a versatile solution that combines manual dipping with dipping arm systems into one compact machine, streamlining the hydrographic process like never before.

Here are some of its standout features

Product Details

Contact Us For Latest Pricing

Total Approximately: ₹20,000 - ₹ 50,000*

Total Approx. : ₹ 20,000 - ₹ 50,000 *

* Above Mentioned Materials Have To Be Purchased Separately It Is Not A Part Of Any Machines You Can Order From Us Separately Or Buy From A Store Near You

* Above Mentioned Materials Have To Be Purchased Separately It Is Not A Part Of Any Machines You Can Order From Us Separately Or Buy From A Store Near You

It’s super easy to start using hydro dip films

It’s super easy to start using hydro dip films

Step by step quick guide

By following these detailed steps, you can successfully apply HGI hydro dip film to decorate a wide range of objects, creating custom designs that are vibrant, durable, and visually appealing. Whether you're personalising automotive parts, sporting goods, electronics, or household items, hydro dipping offers endless possibilities for creative expression and customisation. With practice and attention to detail, you can achieve professional-quality results that are sure to impress.personalising automotive parts, sporting goods, electronics, or household items, hydro dipping offers endless possibilities for creative expression and customisation. With practice and attention to detail, you can achieve professional-quality results that are sure to impress.personalising automotive parts, sporting goods, electronics, or household items, hydro dipping offers endless possibilities for creative expression and customisation. With practice and attention to detail, you can achieve professional results that are sure to impress.

PAINT Booths

A well-designed paint booth can streamline workflow and improve productivity in a hydro dipping business. It provides a dedicated space for painting and dipping processes, allowing for efficient organisation and workflow management. With the right equipment and layout, you can maximise throughput and minimise downtime, leading to increased productivity and profitability.Overall, a good paint booth is a critical investment for a hydro dipping business, providing a safe, controlled, and efficient environment for painting and dipping processes. It contributes to quality, consistency, and compliance, ultimately supporting the success and growth of your business.

Curing Ovens

Consistency is key in hydro dipping, especially when working on multiple items or batches. A drying oven provides consistent and controlled drying conditions, ensuring that each item undergoes the same drying process, which contributes to consistent and high-quality results.